Chapter 10 – Parts Schematic & Optional PV500 Remote Control

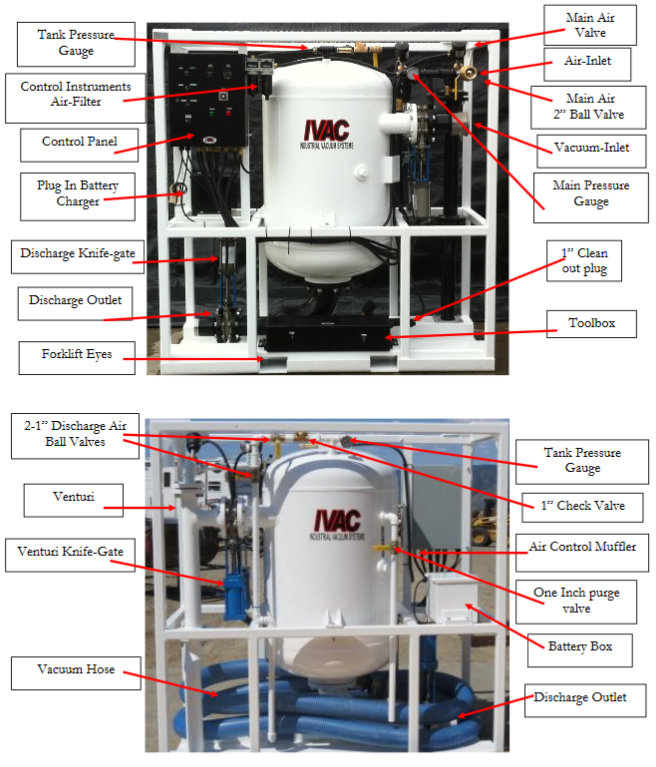

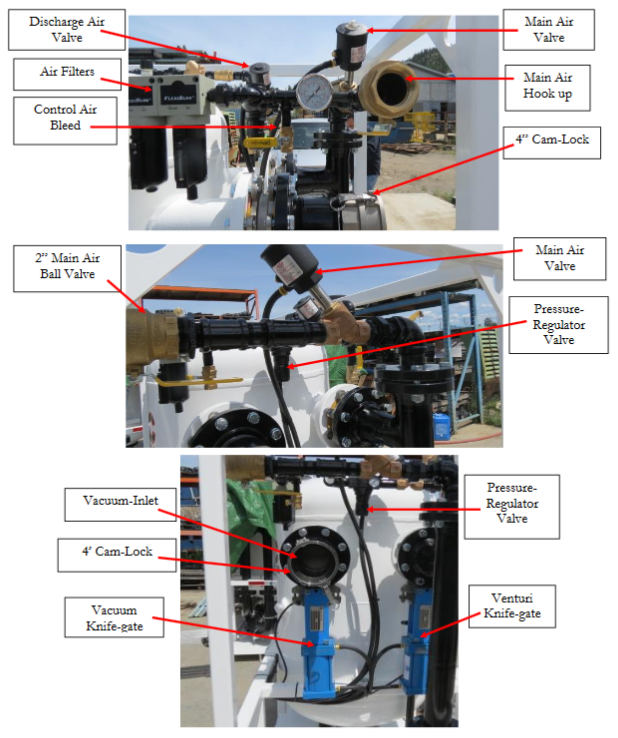

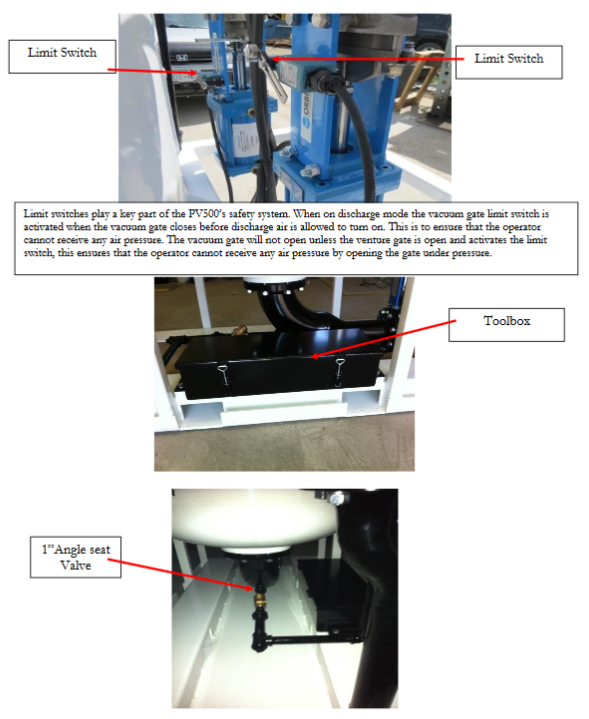

Parts Schematic

Optional PV500 Remote Control

Addition of the PV500 Remote Control.

The remote control allows the operator to manage the main functions on the PV500 Vacuum-Delivery unit. The system can be operated in automatic and manual while using the pennant station provided. Cable extensions allow the operator to manage all the functions from long distances from the unit, even at different mining levels if it is being used to muck raise bore cuttings for example. Additional extensions are available in 50 foot sections from your IVAC dealer. Commonly used so that the driller can operate the equipment from the operator station without needing to be near the main unit. For raise bore cutting mucking the operator can even be on another level of the mine.

Remote/Local Switch

The remote/local switch indicates where the timing for the PV500 will come from. The timer with its’ setting on the main control panel will operate the equipment when “Remote” is selected. When selected (remote) the equipment will first discharge the unit and then go into vacuum mode. The times are controlled by the timer located on the main control panel.

If “local” is selected the vacuum/discharge switch on the pennant station will control the vacuum unit. Therefore selecting “Vacuum” the unit will go into vacuum mode. When the switch is in the “Discharge” position the unit will operate in discharge mode.

Warning: All safety and set-up provisions must be adhered to as per the operator’s manual information. This includes the use of good quality piping or hose and making sure that the discharge pipe or hose is firmly secured.

DO NOT HAND HOLD THE DISCHARGE HOSE – SERIOUS INJURY CAN RESULT! Discharge can be very violent and shutting the switch to “OFF” WILL NOT STOP the flow as any pressure or build-up of pressure is already in the hoses or pipeline and will not be controlled. To stop the unit you are required to shut off the air directly at the unit and manually bleeding the line(s) and is the only sure method of making sure that the line is not charged. Be certain that No Persons can access the area where the unit is discharging.