Chapter 1 – Vacuum Operation

Vacuum Operation

The vacuum units are pneumatic since they operate on compressed air. Compressed air is required to create the vacuum to power the suction hose. Compressed air also provides the discharge air to clear the tank and lines. The discharge air pressure and volume are fully adjustable. The operator controls the discharge airflow to allow you to load something close like a wheelbarrow or mine-car or turn the air on higher and deliver the vacuumed up materials kilometers/miles away.

The vacuum operator must ensure that all lines and fittings are tight and that whip checks are securely fastened on all air hoses.

Wear ear protection whenever the equipment is operating.

Hearing Protection Required

Operator Hose Connections

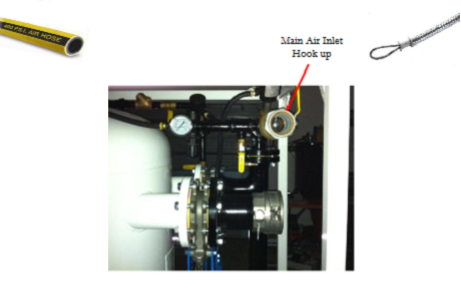

Air Inlet – The air inlet is two inch (2″), this can be National Pipe Thread (NPT), Victaulic (groove type fittings) or other secure means. We do not recommend using “quick type” otherwise know as Chicago type couplings unless you can be sure that there can be no disconnection or vibrating loose when your unit is in operation! Be sure all lines are clean by blowing out your compressed airline before connecting it to the IVAC unit. Make sure all of your airlines, either hose or pipe be tightened before turning on the air to operate the equipment. Whip checks must be installed on all hoses leading to the unit.

Safety Equipment

Be sure to always wear your personal protective equipment (PPE) – Safety glasses, Hardhat, Gloves, Coveralls (oilers), & Hearing protection. These safety items should be considered mandatory and be worn as minimum standards when operating your Ivac units. IVAC technicians can provide crew training for operators and crew for the safe, productive and reliable operation of your vacuum/delivery equipment.

The main two-inch air valve, with main air pressure gauge and the four-inch cam-lock suction