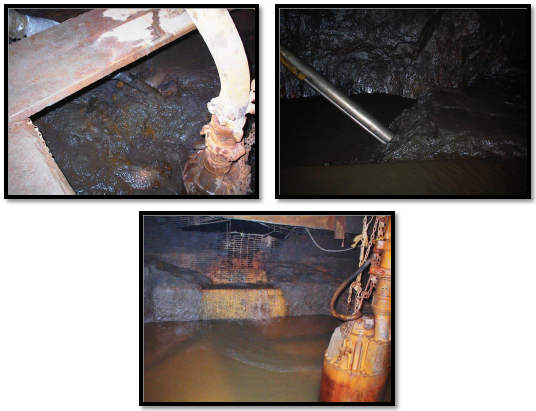

Sump & Ditches

In mines below surface drainage, areas must be provided to store the water before it is pumped to the surface and discharged. Adequate pumping capacity is the only permanent solution to removing water from a mine. A place must be provided for the fines to settle out of the water so they do not damage the expensive high head pump impellers.

IVAC PV500 Sump and Ditch Clean-Out

The sumps must be cleaned of the fines on a regular basis, or costly failure of pumps occurs. Such failures will lead to many mine de-watering issues. A common but very costly method of removing the fines requires the utilization of a scooptram (underground loader). The scooptram is used to pick-up and then relocate the unwanted material to a disposal area. This in itself poses many expensive and commonly overlooked costs to the mining operation, including premature wear and equipment failure on the mobile equipment. Scooptrams are intended to be used for mining ore, so using them for this application not only poses mechanical issues but also causes the equipment to cease productivity while moving the fines. These costs are severely underestimated because the equipment failures do not usually occur right away. The damages done to brakes, differentials and engines are not immediately identified as being due to the improper use of the equipment, and scooptram operation is costly without such damages. Another issue in using scooptrams for this application is their inability to properly handle the materials. Often much of the load is accidentally dropped from the bucket, leaving ramps and haulage ways covered in slime and sludge.

| COST ANALYSIS 6yd Scooptram vs. PV500 Vacuum/Delivery unit |

|

|---|---|

| Assume Distance to Sump from De-Canting Location = 400m | |

| SCOOPTRAM

SCOOPTRAM 4.6 cubic meters every 10 minutes = 27.6m/hr (Scooptram Costs Do Not Include Loss of Mining Production) |

IVAC PV500 Unit

COMPRESSED AIR: $15/hr 4.6 cubic meters every 5 minutes (continuous) = 55.2 cubic meters/hr |

As demonstrated by the above cost comparison, using an IVAC PV500 unit is cost efficient and easily justifiable. Since we can move the equivalent amount of material of a six yard bucketful in under five minutes to a remote location, the slimes are moved for a fraction of the cost as compared to mobile equipment originally intended for mining. With practically zero maintenance costs and the ability to “muck” 100,000 litres per hour of slimes, it is obvious that using an IVAC PV500 unit is more efficient and safe than using a scooptram.

Versus the scooptram, the IVAC unit is performing as it is intended; thus, it is easily determined that the IVAC PV500 Vacuum delivery unit would be the most economical, safest and also the most expedient way to muck out a sump.

IVAC PV500 Sump Sludge and Sand Clean Out