Mine Ventilation

PV500 Mine Ventilation Sand Vacuum

BY-PASS PLUG

Underground mine ventilation provides a flow of air to the underground workings of a mine of sufficient volume to dilute and remove noxious gases (typically NO, SO2, methane, CO2 and CO). The source of these gases is equipment that runs on diesel engines, blasting with explosives, and the ore body itself. The largest component of the operating cost for mine ventilation is electricity to power the ventilation fans, which may account for one third of the electrical power cost for a typical underground mine.

Flow-through ventilation is the main ventilation circuit of a mine. Air enters the mine via internal ventilation raises and ramps, and flows are controlled by regulators and permanently mounted ventilation fans. An auxiliary ventilation system takes air from the flow-through system and distributes it to the mines workings via temporarily mounted ventilation fans, venturi and disposable fabric, or steel ducting. A mine had a drift (tunnel) that was by-passing the costly ventilation air-flow, subsequently not allowing the air to do its job. The drift that was by-passing the ventilation air-flow had no access available for men or equipment due to its awkward location as a result of ongoing mining operations.

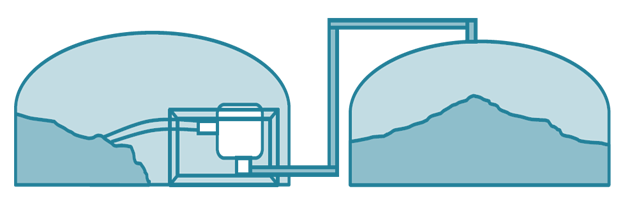

It was determined that the IVAC PV500 Vacuum delivery unit would be the most economical, safest and most expedient way to stop the air loss. A four inch drill hole was drilled thirty meters through the rock from an accessible drift location to the area required to be blocked off. Sand was brought in from the surface with heavy equipment to feed the vacuum suction side which was pumped in until the drift area was completely plugged off and therefore not allowing the ventilation air to flow through it.

IVAC PV500 Mine Ventilation Implementation